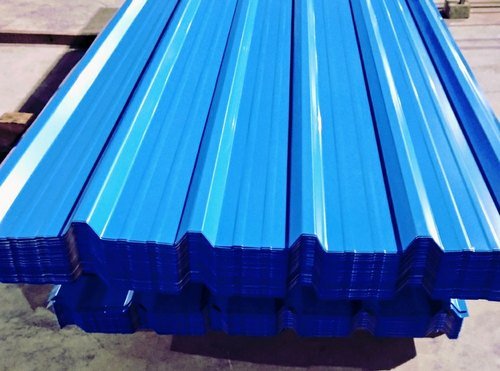

Colour Coated Roof Sheet

Being the biggest Roofing Sheets Manufacturer in the business, we have a state-of-the-art production plant where we can offer unparalleled roofing solutions to both commercial and residential clients. Unlike other manufacturers of roofing sheets, we employ the best materials available to create and deliver our product, which has an extended lifespan. We are therefore one of the most promising producers of roofing sheet.

These sheets are expertly manufactured to withstand inclement weather while boosting the aesthetic appeal of your buildings. To guarantee excellent quality and longevity, the color-coated metal roof sheet manufacturing process entails a number of crucial phases. The first step in the procedure is to choose premium steel or aluminum coils, which are then cleaned and pre-treated to improve coating adherence and remove impurities. Using roll coating techniques, a primer coating is next placed, and finally, a top color coat. These sheets are expertly manufactured to withstand inclement weather while boosting the aesthetic appeal of your buildings.

To guarantee excellent quality and longevity, the color-coated metal roof sheet manufacturing process entails a number of crucial phases. The first step in the procedure is to choose premium steel or aluminum coils, which are then cleaned and pre-treated to improve coating adherence and remove impurities. Using roll coating techniques, a primer coating is next placed, and finally, a top color coat. To make sure the coatings are well-adhered and long-lasting, the coated metal is baked. The sheets are put through extensive quality control testing for adhesion, color uniformity, and thickness after they have cooled. Roll forming machines are then used to cut the coated metal sheets to size and shape them into different profiles. The completed sheets are then sent to clients after being carefully wrapped to avoid damage during transit.